Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

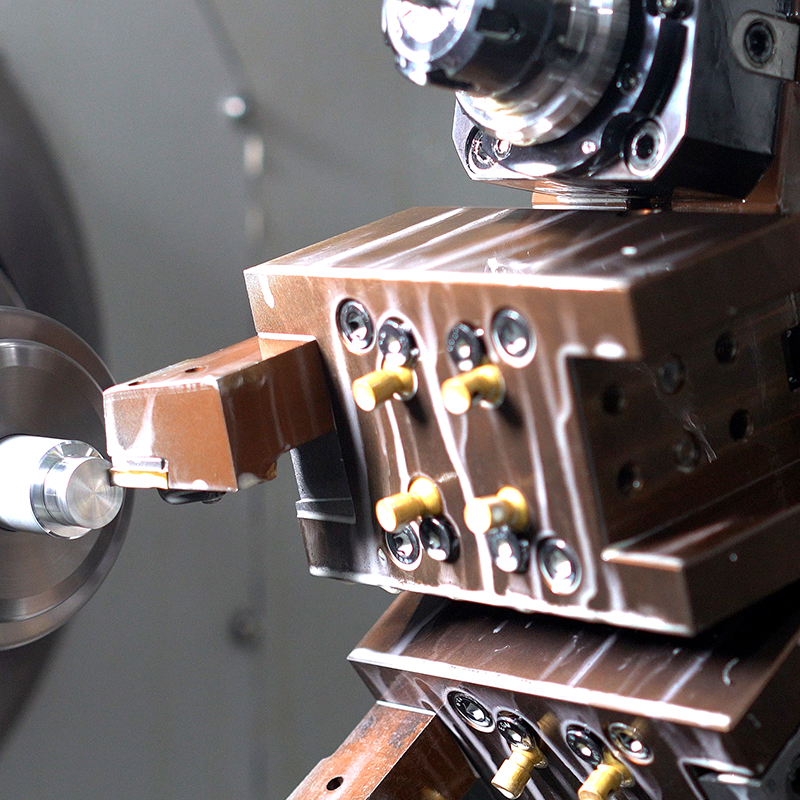

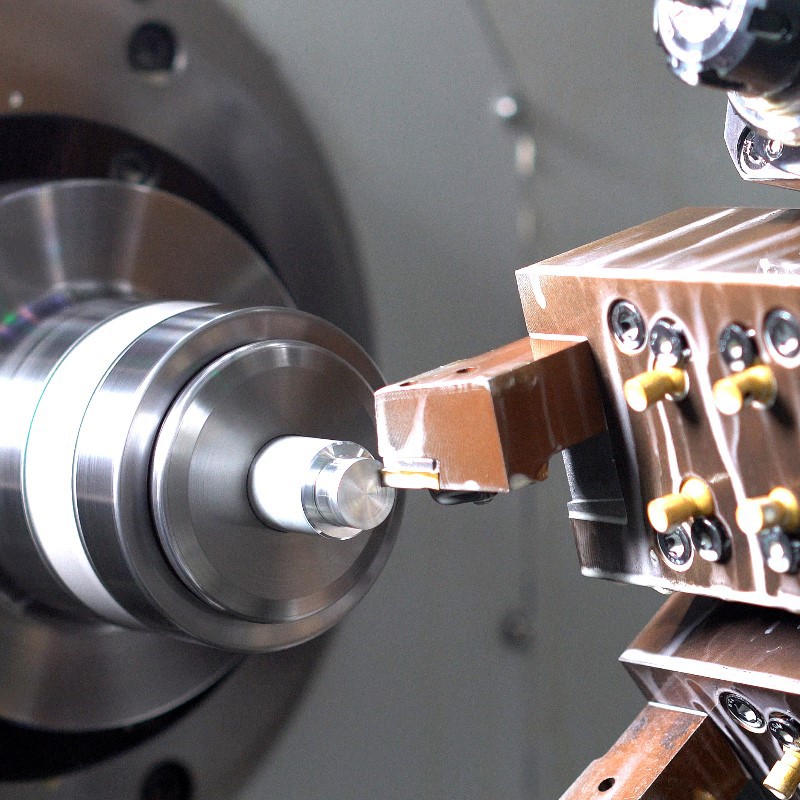

CNC turning service

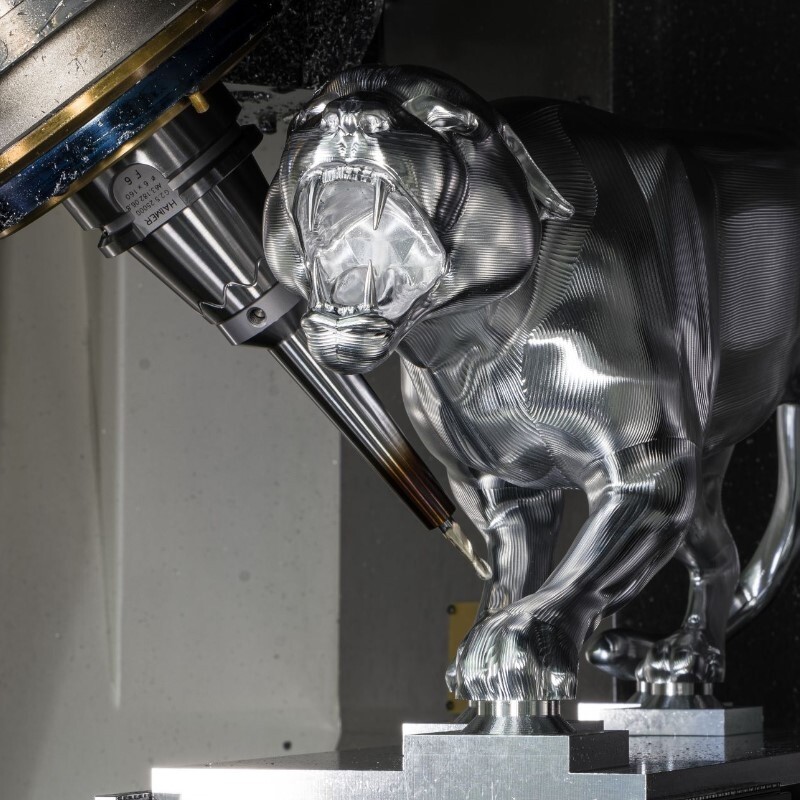

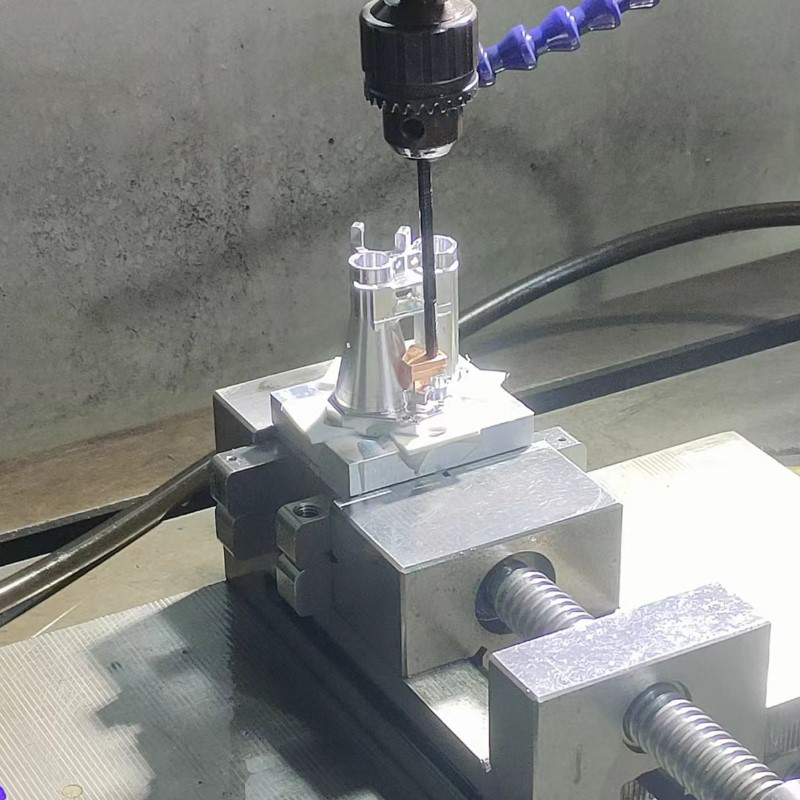

Take advantage of the on-demand CNC turning service and get reliable metal and plastic turned parts for your unique projects. With advanced technologies and expert technicians, Future Parts produces high-quality custom prototypes and end-use production parts. Our CNC turning capabilities allow us to deliver turned parts with high accuracy, regardless of the complexity.

Our precision CNC turning lathes provide low-cost parts for simple and complex cylindrical geometries. We also use Live tooling to create precise, complex geometries for features like axial and radial holes, grooves, slots, and flats. Full automation of these versatile machines allows us to produce hundreds of similar dimensions easier, faster, and cost-effectively.

- Materials for CNC Turning Parts

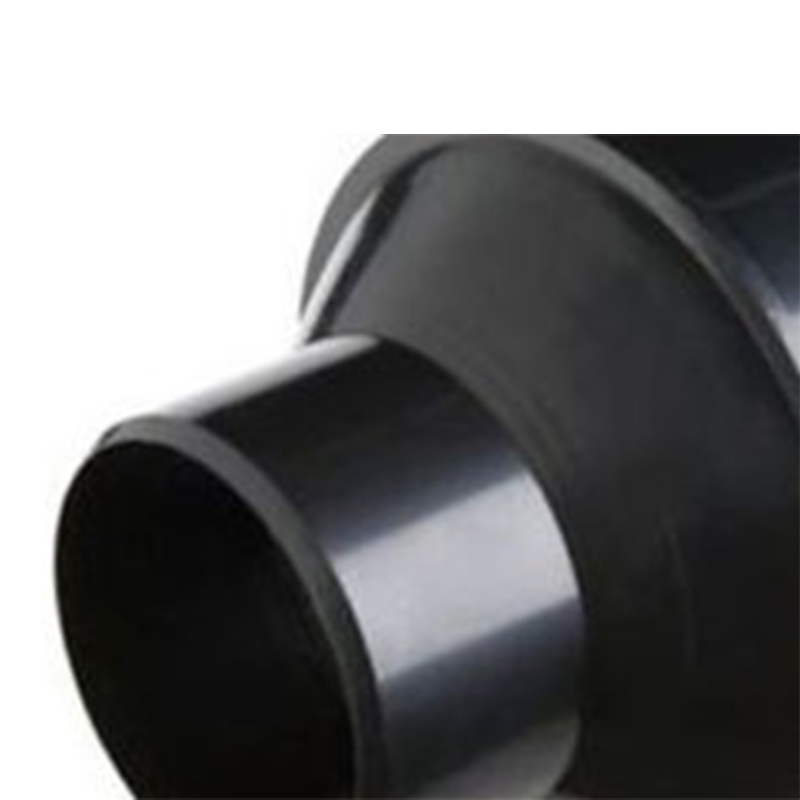

Our CNC turning processes are compatible with a wide range of materials, including machine-grade metals and plastics. Depending on your applications, we can create precise rapid prototypes and low-volume production from various superior-quality materials. Common materials including: aluminum, copper, brass, stainless steel, titanium, plastic(POM,PEEK,HDPE,PET,Nylon,PITE, PVC, PP, ABS, PC, PMMA),etc.

- Surface Finishes for CNC Machining

With a wide selection of surface finishes, Future Parts can help improve the surface qualities of your products. Surface finishes applied to your CNC turned parts aim at improving their appearance, surface hardness and roughness, chemical and corrosion resistance, etc. They also help hide any visible tool marks from areas cut with live tooling. Here are some of your top choices.

|

Name

|

Decsription

|

Materials

|

Color

|

Texture

|

|

|

Anodizing

|

Anodizing improves corrosion

resistance, enhancing wear

resistance and hardness, and

protecting the metal surface.

Widely used in mechanical parts,

aircraft, and automobile parts,

precision instruments, etc.

|

Al uminum |

Clear, black, grey,

red, blue, gold.

|

Smooth,

matte finish.

|

|

Bead Blasting

|

Bead blasting results in parts

with a smooth surface with a matte

texture. Used mainly for visual

applications and can be followed

by other surface treatments.

|

ABS, Aluminum,

Brass, Stainless

Steel, Steel

|

N/A |

Matte

|

|

Powder Coating

|

Powder coating is a type of

coating that is applied as a free- f lowing, dry powder. Unli ke conventional liquid paint which is delivered via an evaporat ing solvent, powder coating is |t ypically applied e lectrostatically and then cured under heat or with ultraviolet 1 ight. |

Aluminum,

Stainless Steel,

Steel

|

Black, any RAL code

or Pantone number

|

Gloss or

semi-gloss

|

|

Electroplating

|

Electroplating can be functional,

decorative or corrosion-related.

Many industries use the process,

including the automotive sector,

in which chrome-plating of steel

automobile parts is common.

|

Aluminum, steel,

stainless steel

|

N/A |

Smooth, glossy

finish

|

|

Polishing

|

Polishing is the process of

creating a smooth and shiny

surface, either through physical

rubbing of the part or by chemical

interference. The process produces

a surface with significant

specular reflection, but in some

materials can reduce diffuse

reflection.

|

Aluminum, Brass,

Stainless Steel,

Steel

|

N/A |

Glossy

|

|

Brushing

|

Brushing is a surface treatment

process in which abrasive belts

are used to draw traces on the

surface of a material, usually for

aesthetic purposes.

|

ABS, Aluminum,

Brass, Stainless

Steel, Steel

|

N/A |

Satin

|

|

Painting

|

Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer’s choosing, while finishes range from matte to gloss to metallic.

|

Aluminum, Stainless Steel, Steel

|

Custom |

Gloss,

semi-gloss, flat, metallic, textured |

|

Alodine

|

Chromate conversion coating, more commonly known by its brand name Alodine, is a chemical coating that passivates and protects aluminum from corrosion. It is also used as a base layer before priming and painting parts.

|

Aluminum

|

Clear, Gold |

Same as before

|

|

Part Marking

|

Part marking is a cost-effective way to add logos or custom lettering to your designs and is often used for custom part tagging during full-scale production.

|

All materials

|

Custom |

N/A

|

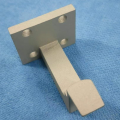

CNC Turning Tolerances

As an ISO 9001 certified company, we machine CNC turning lathe parts to meet tight tolerance requirements. Based on your design, our CNC lattes can reach tolerances of up to ±0.005”. Our standard tolerances for CNC milled metals is ISO 2768-m and ISO 2768-c for plastics.

| Type | Tolerance |

| Linear dimension | +/- 0.025 mm +/- 0.001 inch |

| Hole diameters (not reamed) | +/- 0.025 mm +/- 0.001 inch |

| Shaft diameters | +/- 0.025 mm +/- 0.001 inch |

| Part size limit | 950*550*480mm 37.0* 21.5 * 18.5 inch |

The Advantage of product

Material Removal Speed:

CNC lathes quickly remove substantial amounts of material, contributing to efficient production.

Fine Cutting Tools and Surface Finish:

Utilizing precision tools like Guhring cutters ensures an excellent surface finish without the need for additional post-finishing.

Effective for Round Features:

- Turning, as performed by CNC lathes, is the practical choice for creating internal and external threads, long bores, tapers, ring grooves, and other round cross-sectional features.

- While CNC mills can achieve some of these features, the process is slower and not optimized for maximum efficiency.

The Feature of product

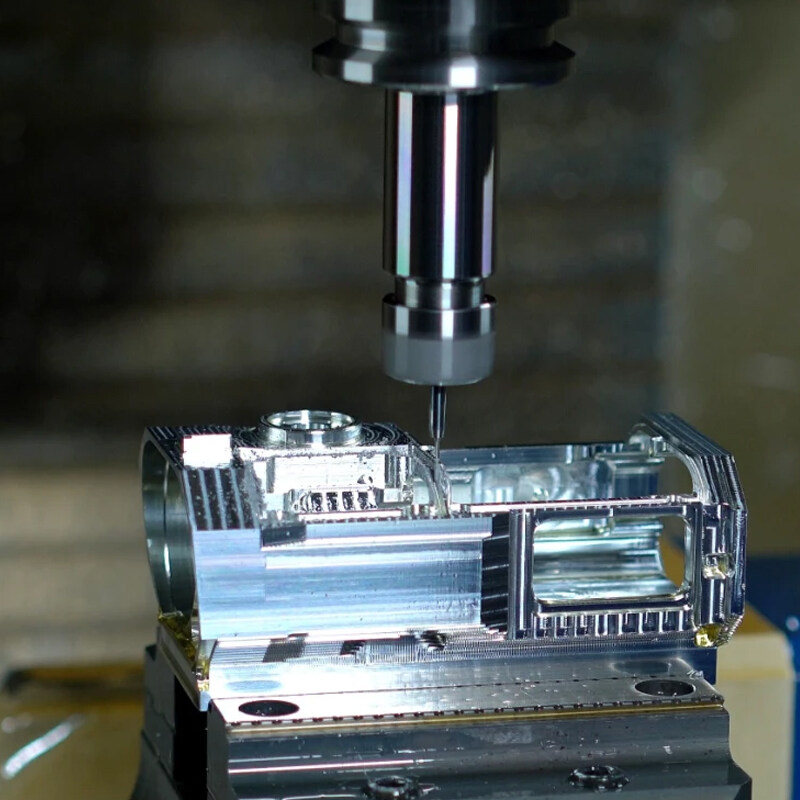

Machining Process:

- CNC milling involves rotating cutting tools against a stationary bar stock or workpiece.

- CNC lathes rotate the bar stock or workpiece against a stationary tool.

Surface Suitability:

- CNC milling is more suitable for machining irregular and flat surfaces.

- CNC lathes are best suited for cylindrical or conical parts.

The Production Process of product

The CNC machining process begins by designing a part in CAD software. This design is then converted into a set of machine commands using CAM software. The CNC machine reads these commands to precisely cut and shape the material, producing a finished part that matches the digital design.